For Robust, High-Quality and Fast Processes

AI-powered Settings Optimization.

The Challenge

New molds come in different forms and levels of complexity. It can take up to 2 days or even longer, with countless iterations of the mold, until the series production process is released. Especially the determination of optimal setting parameter values is tedious. Even more so in current times, when experts are rare and not easily kept in the company.

OSPHIM’s Solution

With the OSPHIM-App you will unlock the full potential of your data! Based on the asset management and data connectivity, the App will acquire automatically production data from your process. With the experimentation feature, you control the trials run on the machine and use the AI models to finally optimize your settings – and that in record time!

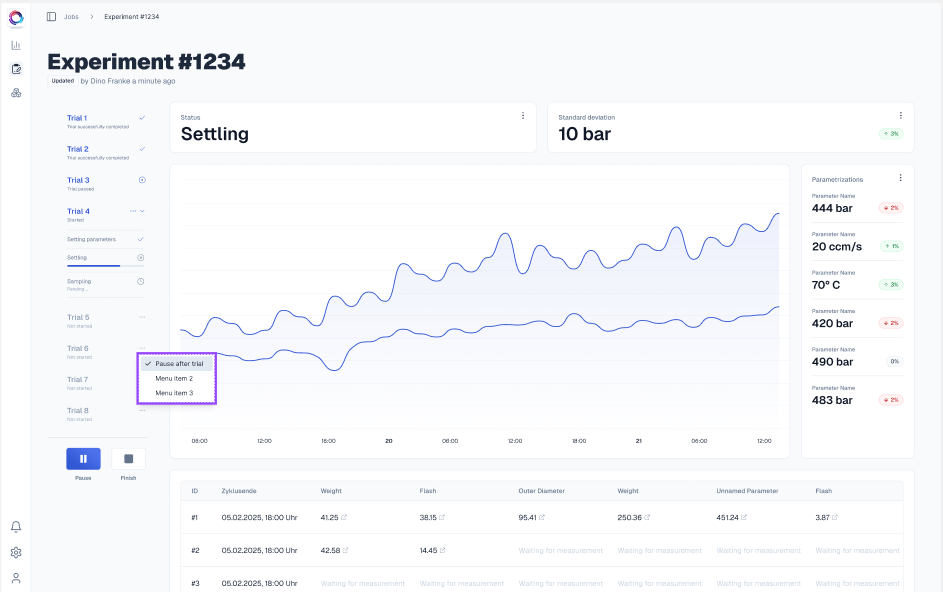

Gather Experimentation Data with the OSPHIM-App

Characterize your process interactively and generate on-point process data for the optimization.

- Fully manageable on the OSPHIM-App

- Get instant insights about your correlations and mold capability

- Prepares the datasets automatically for the AI Read more about the Experimentation arrow_right_alt

Flexible optimization focus

Optimize the settings based on your selection of most relevant objectives.

- Consider part quality and process robustness

- Simultaneously optimize energy consumption and cycle times

- Generate different settings, e.g. with focus on fast or sustainable production

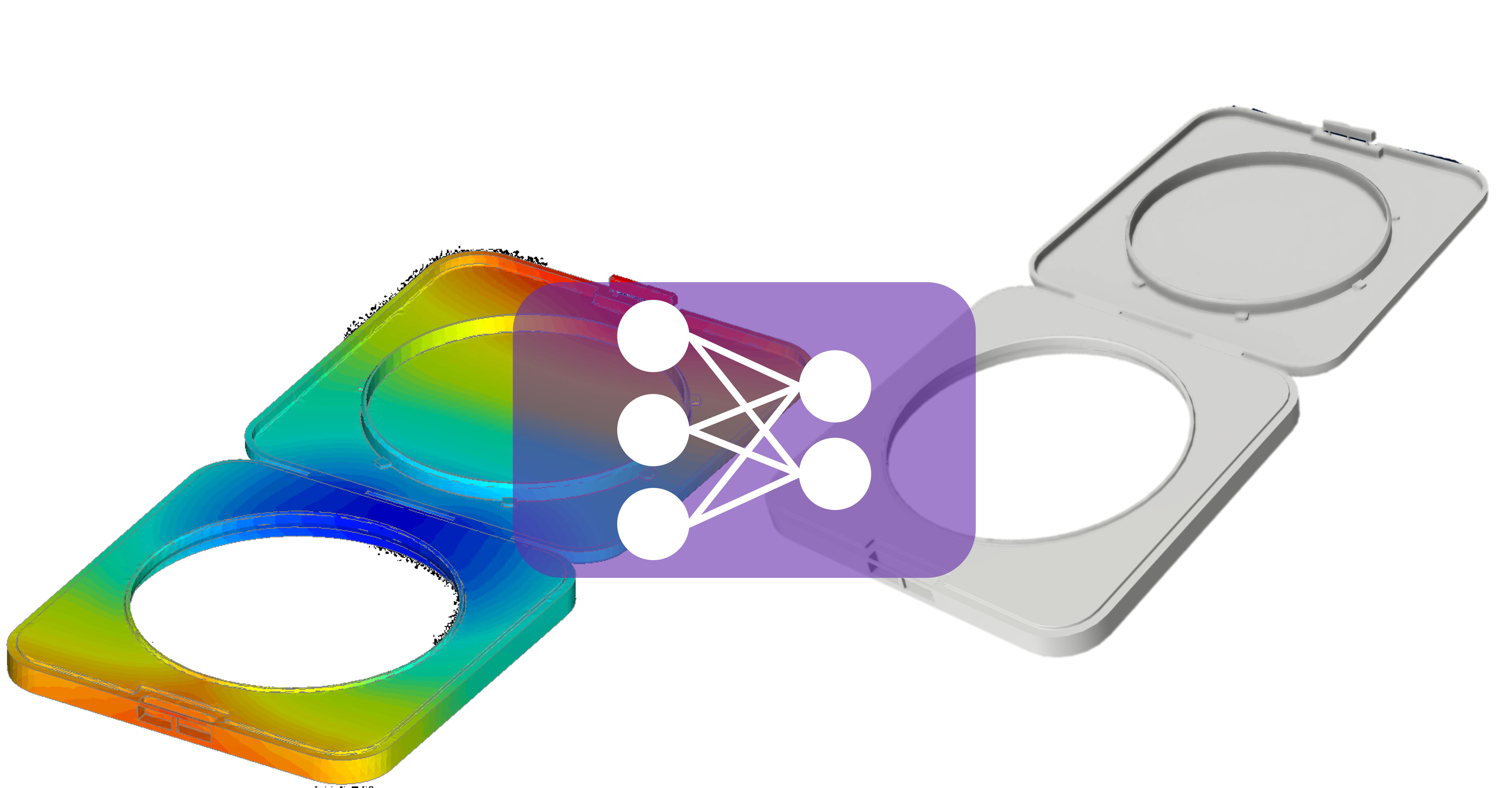

Combine simulation and real data

Our solution is special, as the AI in the background gladly accepts simulation trials you have run before. Just upload them via the OSPHIM-App and benefit from even faster setups!

- Support for the most common injection simulation software results

- Application of advanced AI techniques without coding

- Further reduction of necessary trials and time until series production

Automatic Process Window Identification

Get an idea about the process boundaries in case you need to make some adjustments

- Evaluate the maximum process window

- Concrete analysis regarding sensitive parameters

- Help for minimally invasive corrections during series production

FAQs

Making Data Smarter with Semantics in Injection Molding

As production processes are getting increasingly complex and demanding regarding quality and efficiency, the role of data in decision-making, process optimization, and innovation is unparalleled.

Read more

Industry Trends @ NPE 2024: Energy-Saving Solutions

NPE 2024 The Plastics Show

Read more

How Data Drives Recycled Plastics Adoption

Data-driven insights optimize recycling, ensuring quality, compliance, and sustainability in a circular economy.

Read more

Want faster mold-to-production times?

With our features you can improve your workflow for the setup of new molds. Get in touch with us today to start capitalizing on our AI technology!