Prevent Scrap and Downtime

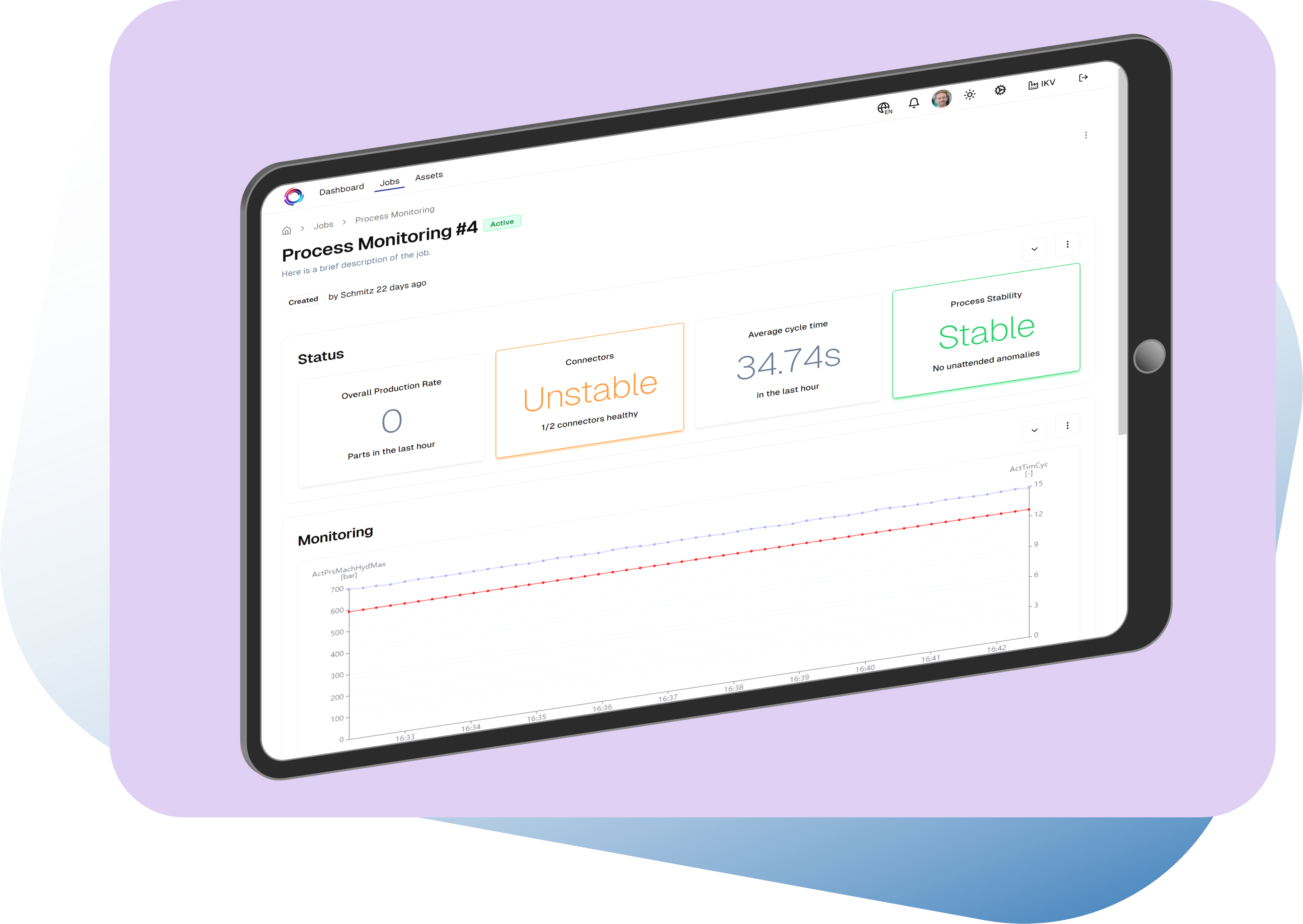

AI-powered Process Monitoring.

The Challenge

Process monitoring in injection molding is challenging due to complex interactions between material properties, machine settings, and environmental factors that cause subtle quality variations. Traditional systems struggle with early-stage deviations, requiring AI-driven analysis to detect patterns, adapt to changes, and provide real-time insights.

OSPHIM’s Solution

OSPHIM enables intelligent process monitoring by continuously analyzing production data with AI-driven anomaly detection, identifying deviations before they impact quality. The system adapts to changing conditions, providing real-time insights and optimization suggestions to ensure a stable and efficient injection molding process.

Unlock series production features

✓ Get access to all production related features

✓ Save time by a one-stop-shop view

✓ Integrate with common ERP and MES systems

Automatically detect Anomalies

✓ Employ OSPHIM’s anomaly detection

✓ Receive alerts for deviating processes

✓ Prevent downtime and scrap swiftly

Turn events into valuable information

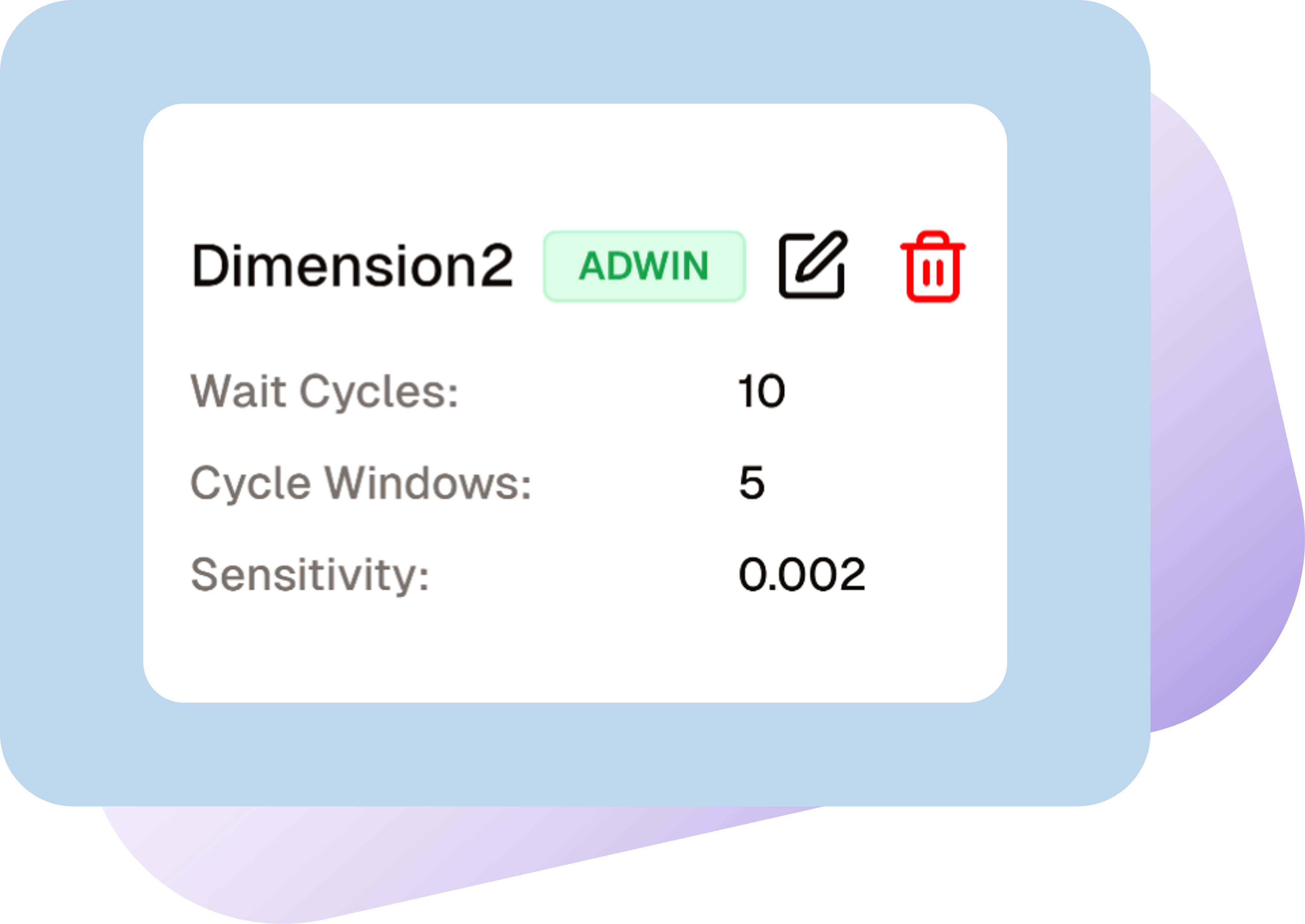

✓ Track or react to anomalies or events

✓ Store disturbance reasons and counter measures

✓ Train the system on your specific process behavior

FAQs

Become an Expert

Already use a MES? – Where OSPHIM Complements it!

OSPHIM complements existing MES installations by exposing powerful data- and process oriented features for an efficient injection molding production…

Read more

How Data Drives Recycled Plastics Adoption

Data-driven insights optimize recycling, ensuring quality, compliance, and sustainability in a circular economy.

Read more

Making Data Smarter with Semantics in Injection Molding

As production processes are getting increasingly complex and demanding regarding quality and efficiency, the role of data in decision-making, process optimization, and innovation is unparalleled.

Read more

Want to make your production more efficient?

Let’s talk about the application for your injection molding production!