Automatically detect process deviations

AI-driven Anomaly Detection.

What to expect from Anomaly Detection?

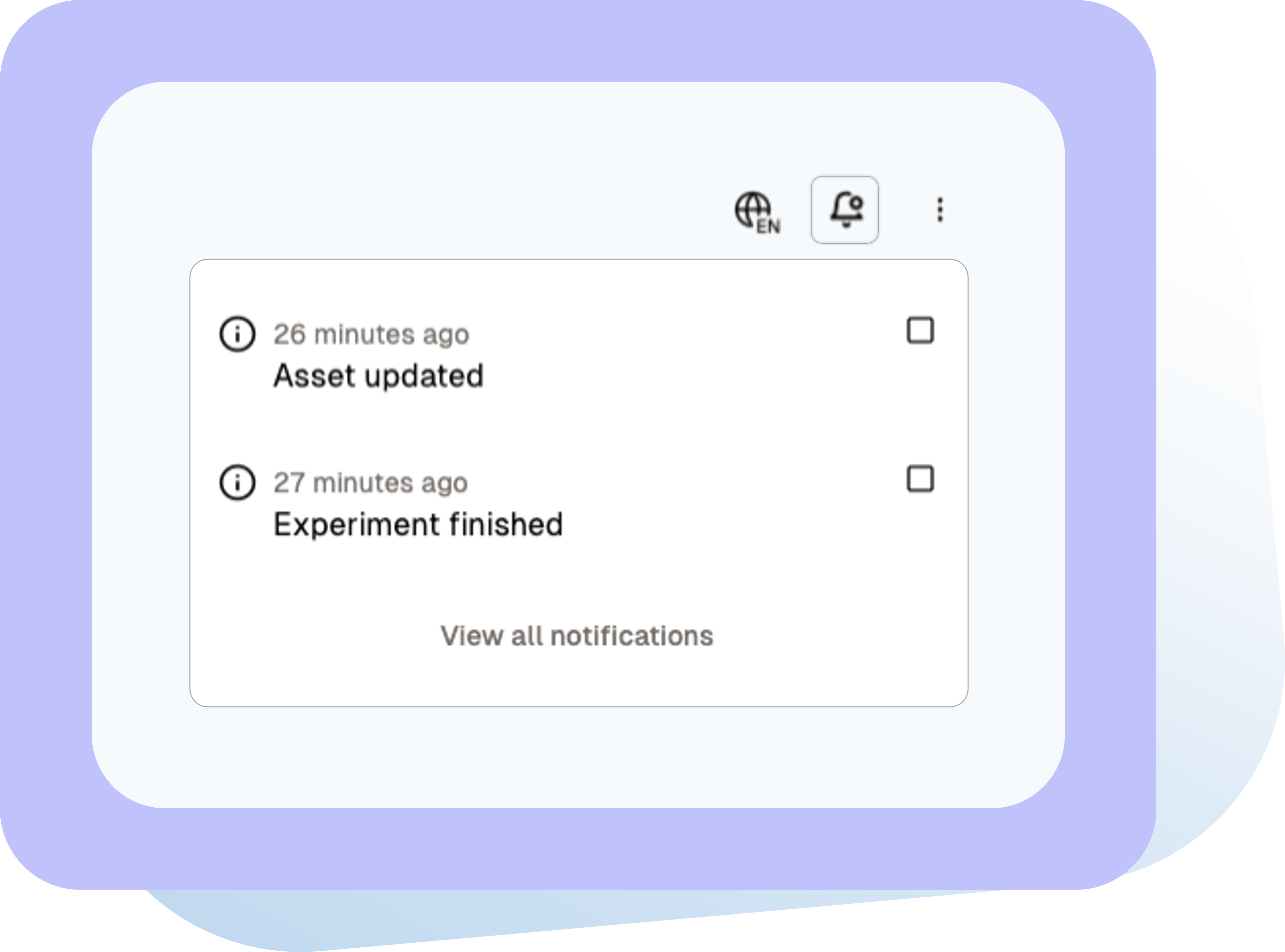

Early Warning System

Get instant alerts when anomalies occur, allowing your team to take immediate action and avoid costly downtime.

✓ React swiftly to any change

✓ Prioritize machines by severity

✓ Minimize scrap and downtime costs

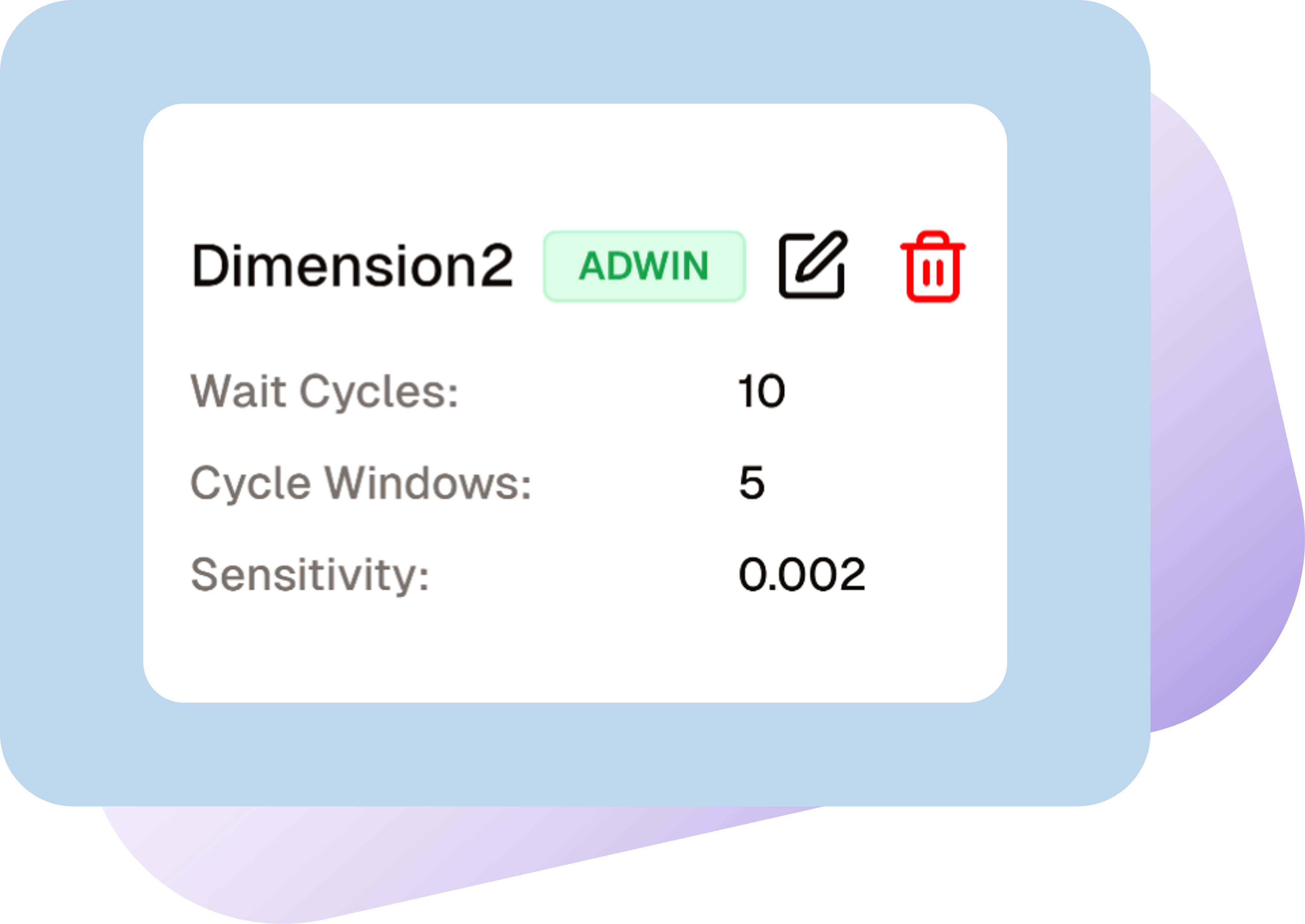

Dedicated AI detection models

Select from different AI models to find deviations or just rely on the validated default by OSPHIM.

✓ Expert Selection of Anomaly Detectors

✓ No coding necessary

✓ Control from everywhere

FAQs

Root Cause Analysis

Continuously Improve your Production Performance retaining Knowledge about Solutions

✓ Identify the root causes of process variations

✓ Track and Store the root causes and counter measures

✓ Enhance Efficiency from faster Problem Solving with the OSPHIM-App

Become an expert

Already use a MES? – Where OSPHIM Complements it!

Making Data Smarter with Semantics in Injection Molding

Participation of OSPHIM@Haitian Open House 2024

Is my production ready?

Get in touch with us and find out in as much as 20min how to get OSPHIM up and running at your plant!