Capture, analyze and utilize your production data

Intelligent Data Acquisition

The Challenge

Injection molding facilities generate vast amounts of process data, yet much of it remains underutilized. Without a structured approach to data acquisition, manufacturers struggle with inconsistent quality, inefficiencies, and undetected anomalies. Manual data logging is time-consuming and prone to errors, limiting the potential for data-driven decision-making.

OSPHIM’s Solution

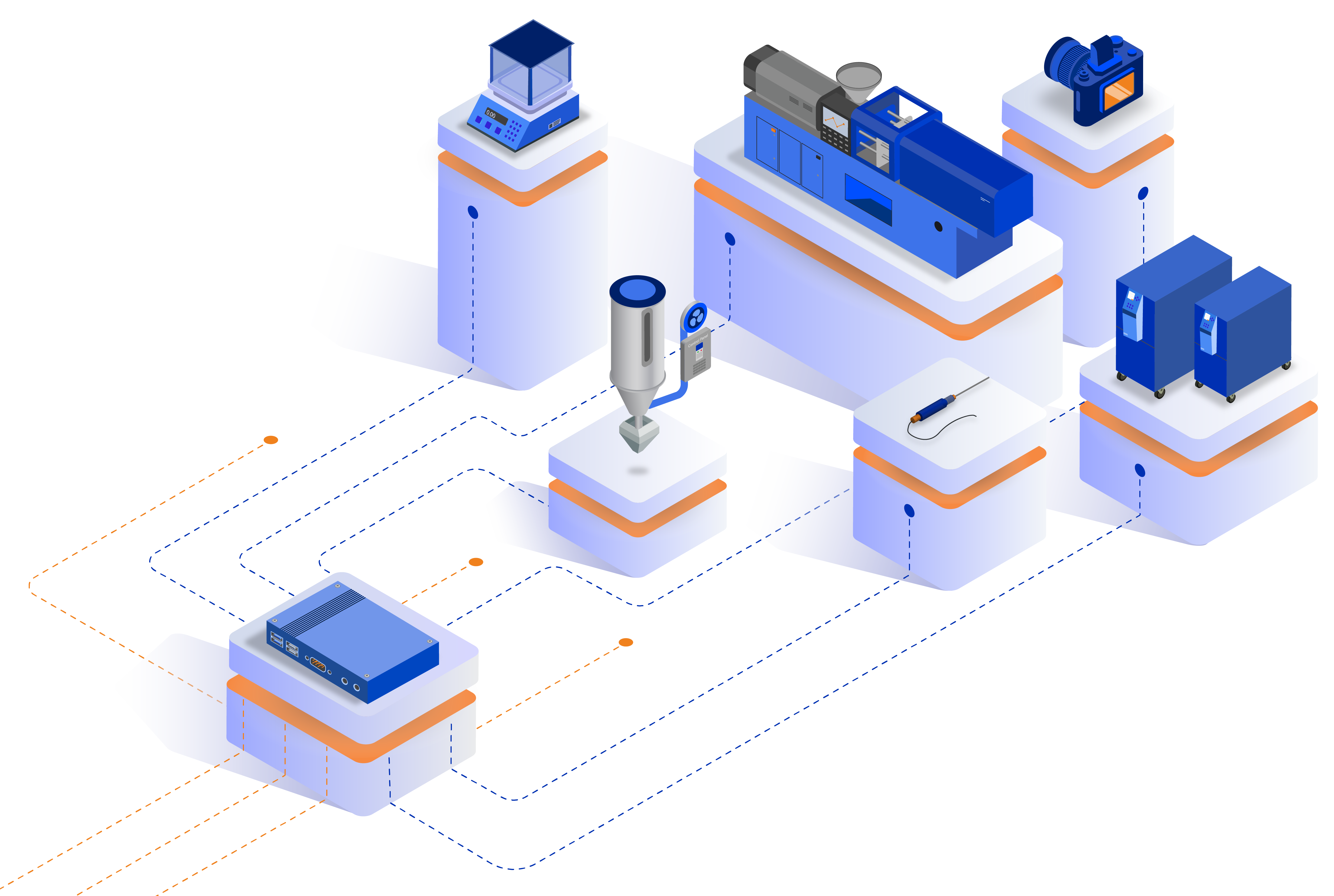

OSPHIM provides a seamless, automated data acquisition system that collects, processes, and visualizes production data in real-time. By integrating with your existing machinery and sensors, OSPHIM enables manufacturers to gain deep insights into their operations, ensuring stable processes and continuous optimization.

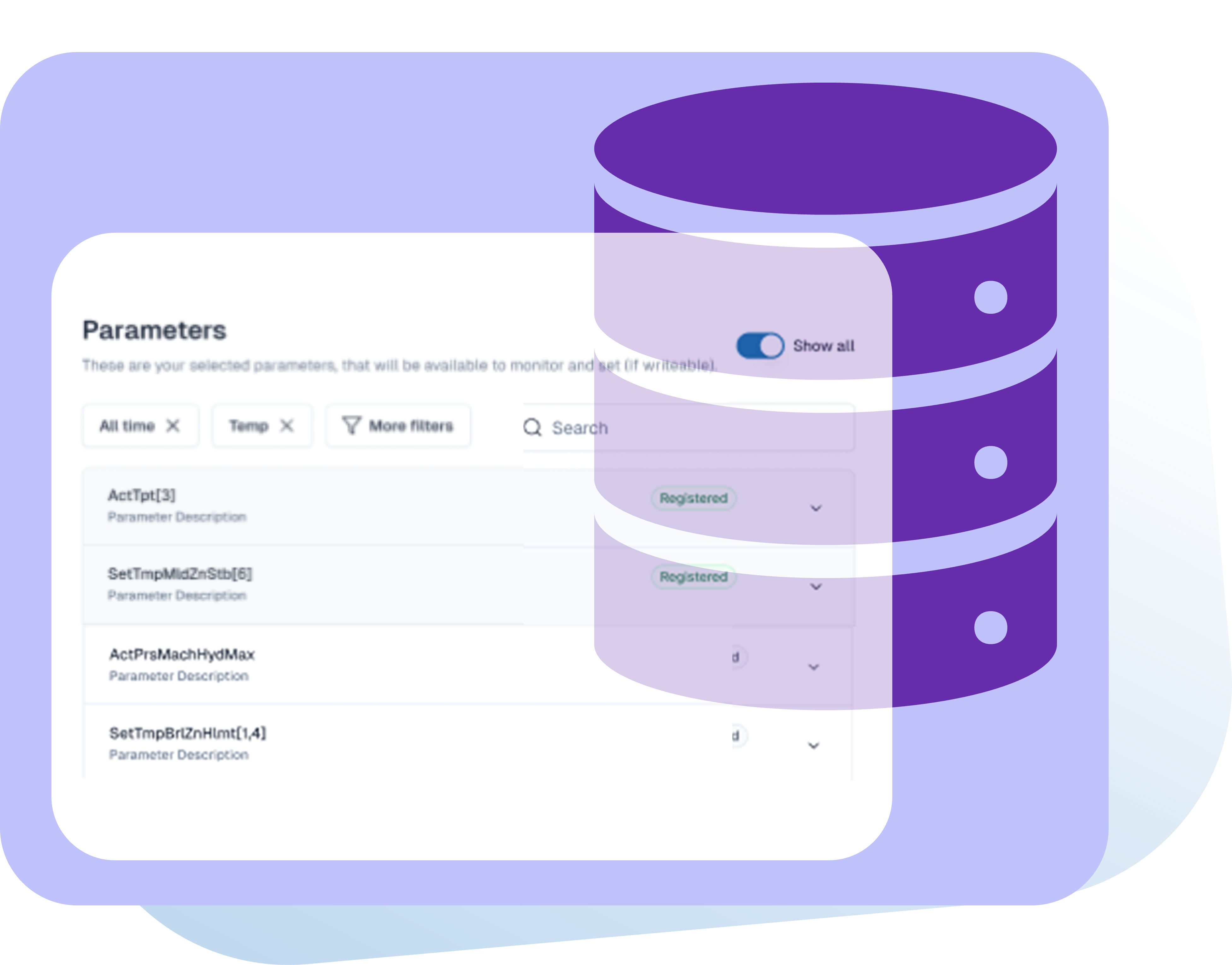

Select your parameter for acquisition

With OSPHIM’S easy interface, you can configure the relevant parameters for storage yourself.

- Change and add parameters at any time

- No additional fees

- Collect as many parameters as you want

OSPHIM’s semantic data acquisition

Semantic data acquisition in injection molding is crucial for transforming raw machine data into meaningful insights by linking process parameters with material properties, part geometry, and environmental conditions. This structured approach enables more accurate anomaly detection, root cause analysis, and process optimization. By understanding data in context, manufacturers can improve quality, reduce waste, and enhance production efficiency.

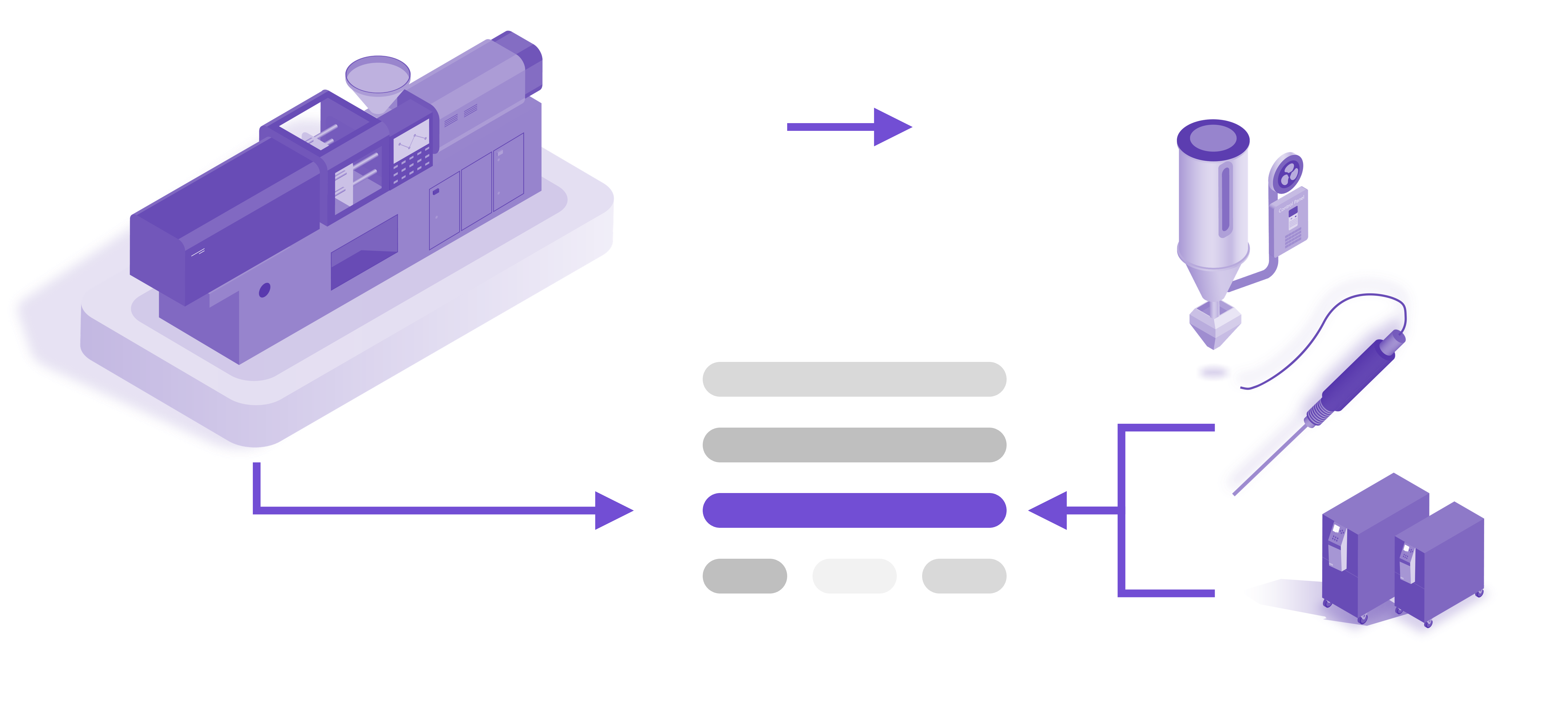

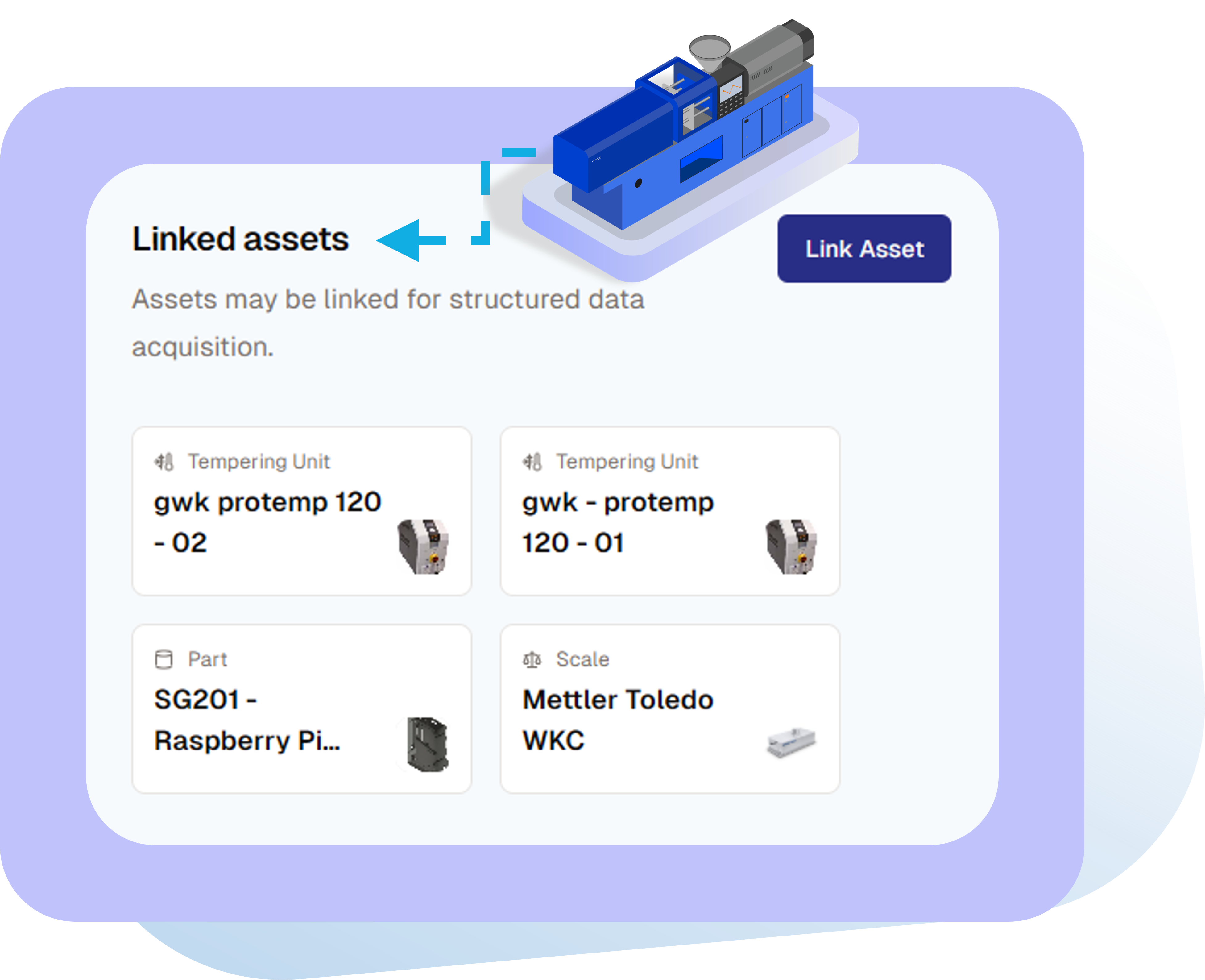

Structured Data Aqquisition

Associate your assets with each other to acquire meaningful, complete data from your production.

- Matching process and quality data

- Retrace your production

- Simplify data extraction and analysis

Easy and Flexible Visualization

As soon as you are connected to the OSPHIM-Cloud, use the Dashboards in the OSPHIM-App to visualize your data – either for the whole plant or specific for single machines!

- As many Dashboards as you want

- Customizable views and arrangements

- Private and Public Dashboards Go to Dashboard Feature arrow_right_alt

FAQs

Cloud Security @ OSPHIM

Data Protection

Encryption, GDPR Compliance and Hosting in Germany

Reliability

Frequent Backups, Redundancy and High Uptime

Access Control

SSL / TLS, Authentication & Authorization

Network Security

Minimal number of ports, IaaS by Microsoft Azure

AI Action Summit in Paris: Opportunities for the Plastics Industry

AI Action Summit in Paris: Unser Blick zu Chancen und Risiken für die Kunststoffindustrie

Read more

Already use a MES? – Where OSPHIM Complements it!

OSPHIM complements existing MES installations by exposing powerful data- and process oriented features for an efficient injection molding production…

Read more

CONNECT Moldflow User Meeting 2024 – A Highlight in Frankfurt!

At the heart of my participation was my presentation on “Intelligent Parameter Optimization in Injection Molding through Human-Machine Cooperation in Simulation and Reality.” I introduced our project, which developed an innovative solution…

Read more

Unlock the Power of Data-Driven Manufacturing

Gain full control over your production data with OSPHIM’s intelligent Data Acquisition System. Contact us today to learn how our technology can transform your operations.