You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDIGITAL PRODUCTION

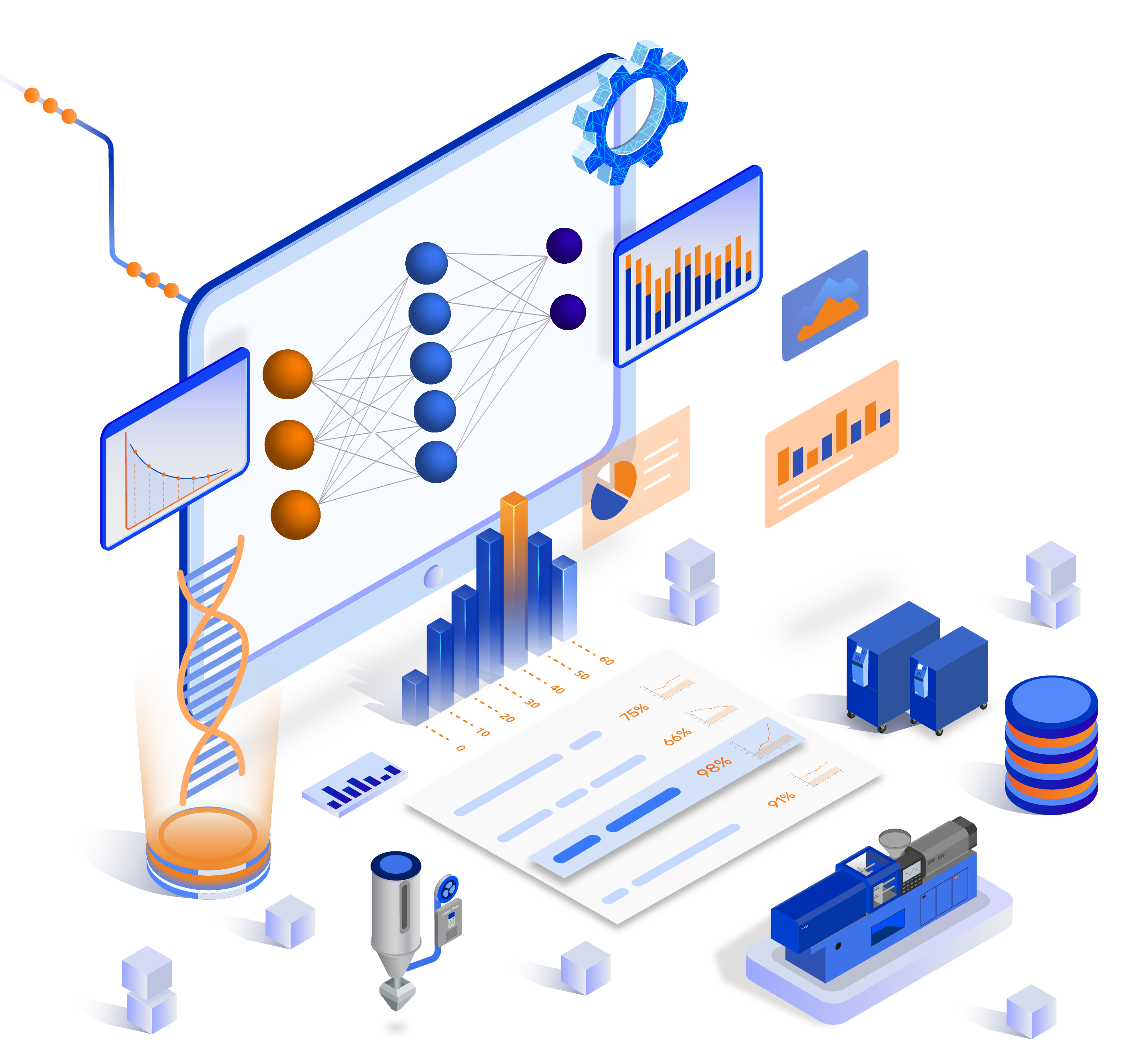

Optimize your Injection Molding Process

Wherever you experience hurdles, in quality, cycle time, automation or availability of experts for your production. OSPHIM supports your production in optimization and all-day tasks to reduce your costs and efforts!

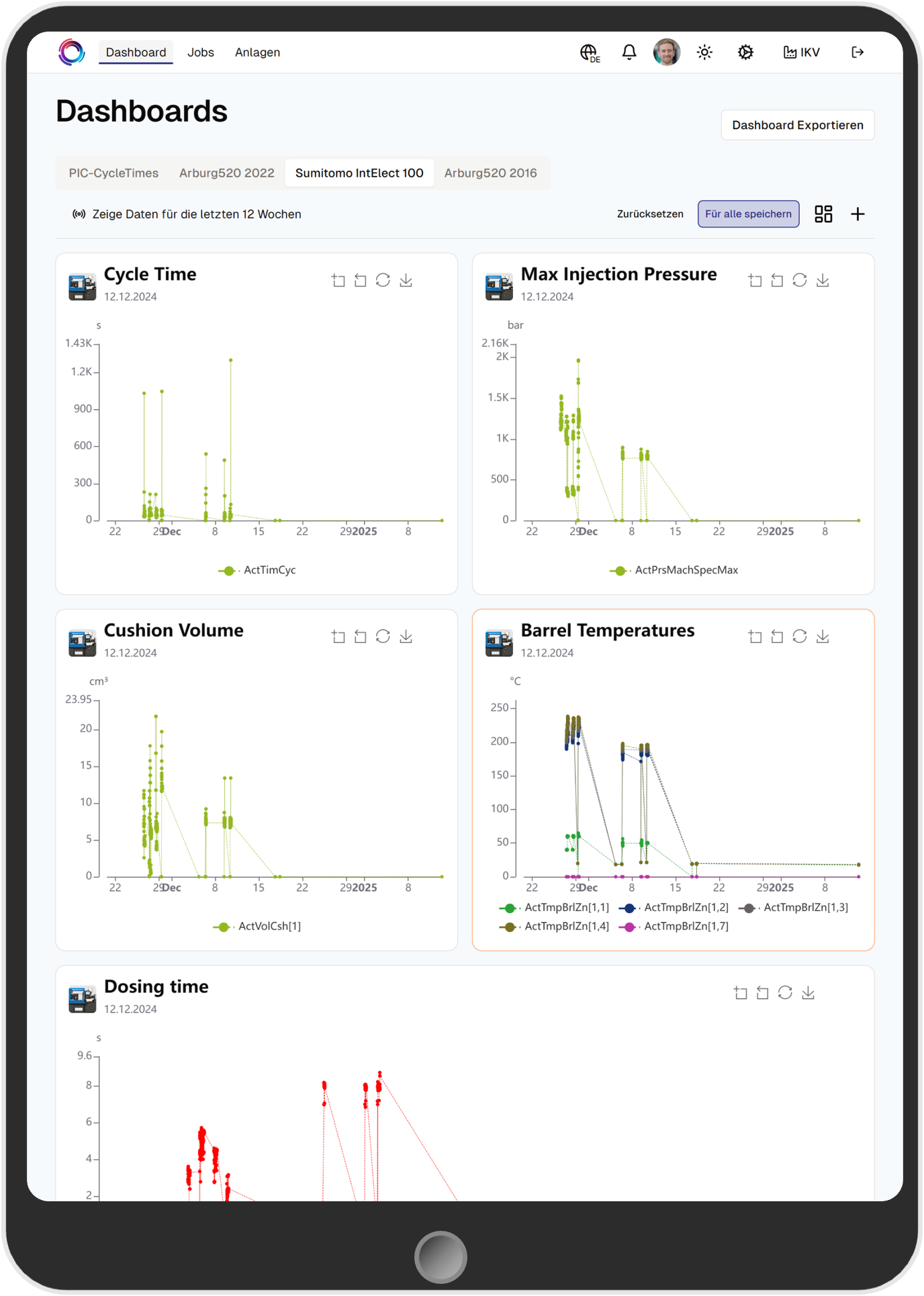

Turn your Data into Value

You can do more than data acquisition! OSPHIM transforms your production data into concrete recommendations how to increase production speed and achieve on-point part quality!

Why OSPHIM

Dr. Julia Gebauer

Innovation Management

We want to continue working with OSPHIM to deepen the integration of our data into the continuous improvement process (CIP). Initial trials with OSPHIM’s AI show a clear path to a solution and will future-proof us in order to remain competitive in the long term.

OSPHIM-App

OSPHIM-Cloud

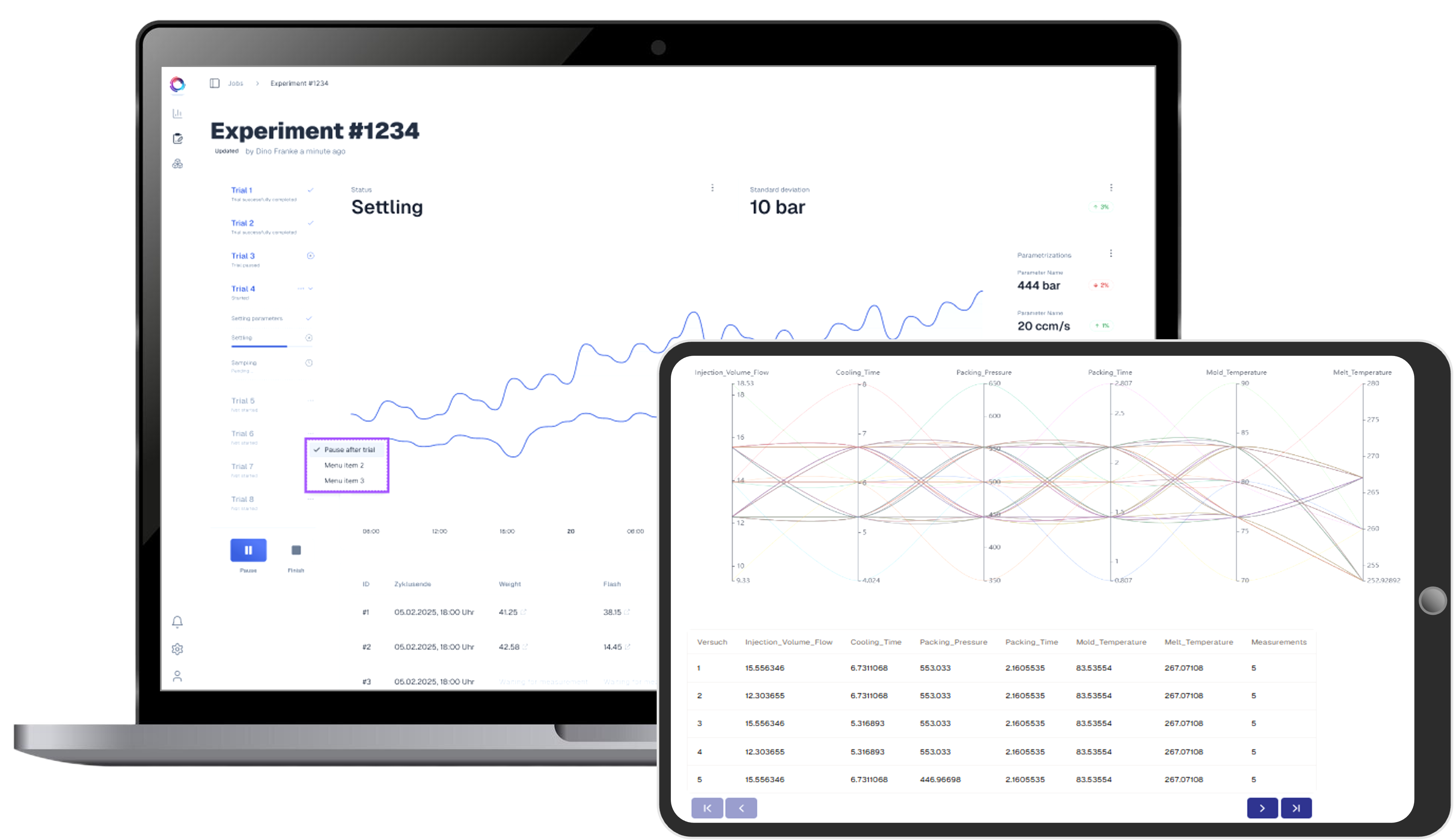

Process Development on a new level

OSPHIM’s platform supports your injection molding industrialization process on all its steps!

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBoost your production with OSPHIM’s solution

OSPHIM combines Process Know-How and Technology

Which is your field of application?

Data Visualization, New Process setup or support during Series Production – Select your package!

Insights

Start your digital production now!

Get a quoteWhat you get:

- Unlimited users

- Unlimited data acquisition

- Unlimited dashboards

- Unlimited Analyses & Exports

Used by:

Setup

Optimize your setup times for new molds!

Get a quote

Everything in Insights +

- AI model training suite

- Process Optimization

- Experimentation Manager

- Diagnostic Analytics

Used by:

Production

Prevent scrap before it even occurs!

Get a quote

Everything in Insights +

- Process Monitoring

- Anomaly Detection

- Process Alerts

- Knowledge Management

Used by:

Enterprise

Fully integrate OSPHIM into your production!

Get a quoteSetup and Production +

- Module Individualization

- Separate Deployment

- Brownfield Integration

- VIP Support

Used by:

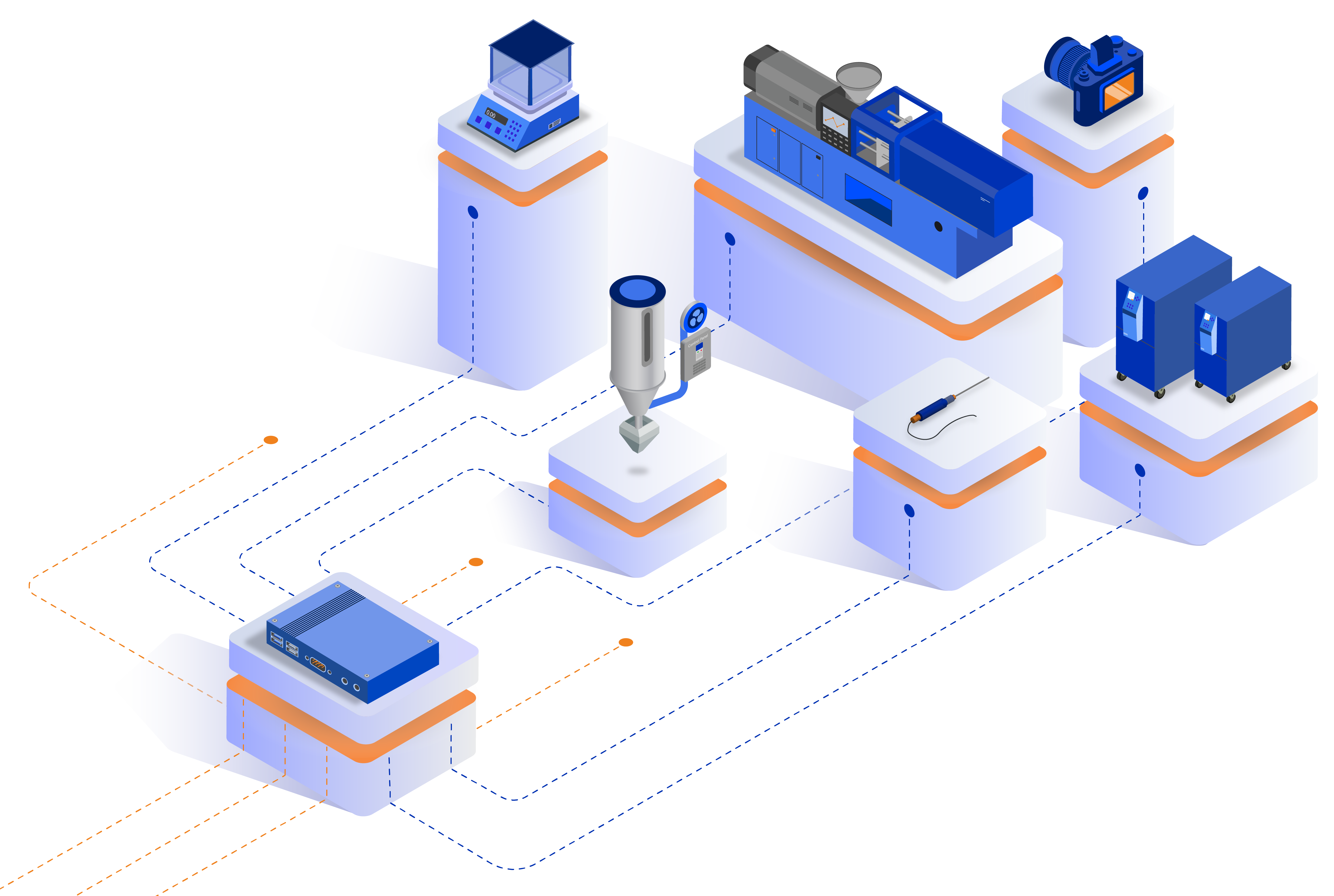

How to Get Started!

Get in touch with OSPHIM and start your journey! We will first enable your access to the OSPHIM-Cloud and assure that your are set regarding data acquisition and machine connectivity!

Questions & Answers

Ready to make the most out of your data?

Let’s talk about the application of OSPHIM in your production!