OSPHIM: Your Digital Assistant for Optimized Production

The OSPHIM Solution

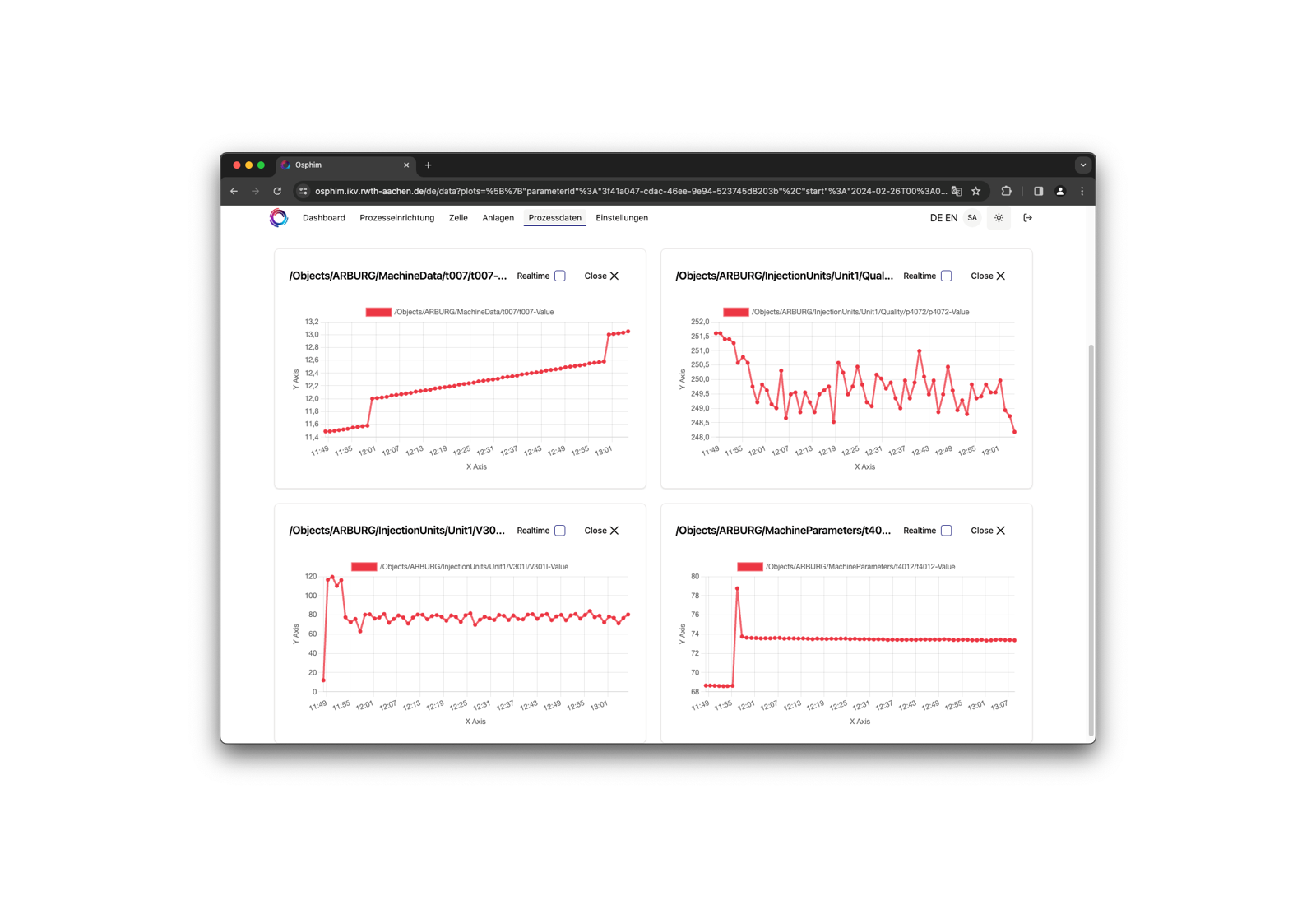

OSPHIM offers an advanced digital ecosystem tailored for the plastics processing industry, using AI to optimize manufacturing processes to achieve significant efficiency gains.

Data-based support in your all-day tasks to drive efficiency

OSPHIM’s platform harbors a multitude of AI-integrated features for production optimization. If you are struggeling with long setup times or high scrap rates during series production, our data-based analyses can support your optimization goals. Take a look at the supported use cases in plastics manufacturing!

Access your machine’s data through an easy to use edge device

The data from most machines can be acquired with OSPHIM either by an ether or serial based interface, such as OPC-UA or RS-485. The OSPHIM-BOX supports a multitude of common interfaces in plastics manufacturing, communicates as proxy with the machine and keeps your data safe through encryption. It needs only one port to deliver your data to the platform!

Interested in similar results?

Contact us today to explore how our AI solutions can optimize your injection molding operations and drive success

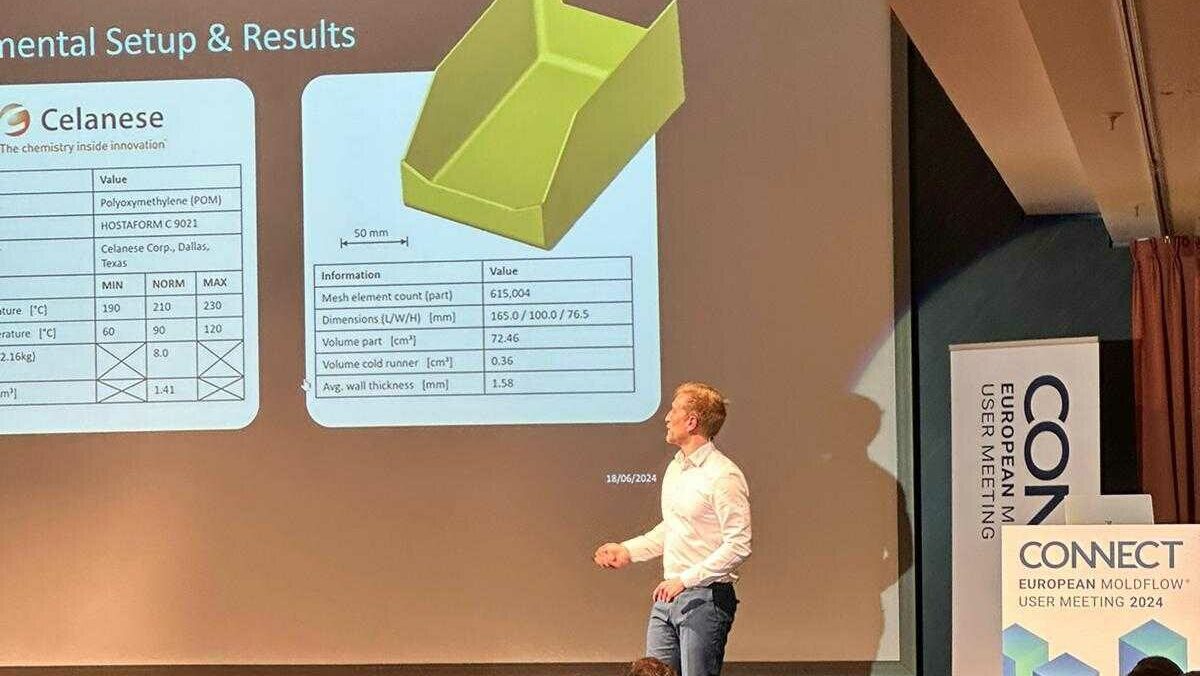

CONNECT Moldflow User Meeting 2024 – A Highlight in Frankfurt!

Already use a MES? – Where OSPHIM Complements it!